- Home

- Drilling Machines

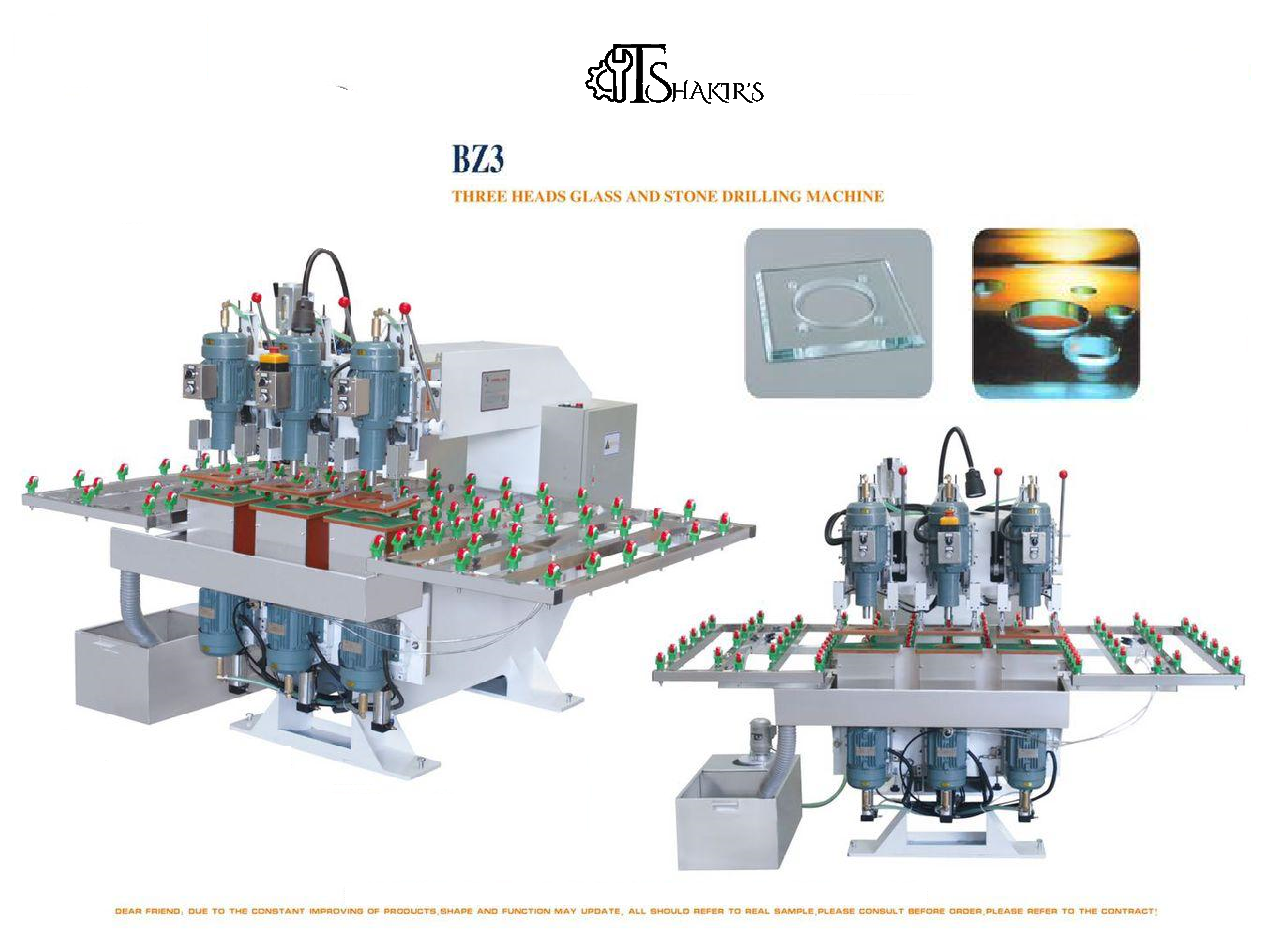

Three Head Glass Drilling Machine

In the glass fabrication sector, a specialized piece of machinery called a three-head glass drilling machine is used to efficiently and precisely drill holes into glass panels. It is frequently employed in situations where complicated drilling patterns or many holes are needed.

How It Works

- Triple Head Drilling: This technique consists of three independently operating drilling heads that enable the simultaneous drilling of many holes at various places in a single operation.

- Adjustable Spacing: This feature allows for flexibility in design by allowing the spacing between drilling heads to be changed to suit different hole sizes and patterns.

- High Precision: Makes use of cutting-edge control technologies to guarantee precise drilling and placement, lowering the possibility of mistakes and broken glass.

- Automated Operation: Consists of computer-controlled depth, speed, and positioning parameters that minimize operator involvement and guarantee constant quality.

- Long-lasting performance is ensured by the sturdy materials used in the construction, which can withstand varying glass kinds and thicknesses.

- Safety Mechanisms: Contains safety measures including sensors to identify misalignment or movement of the glass in order to safeguard operators and avoid glass breakage

Applications

- Shower doors

- Glass partitions

- Glass shelving

- Architectural glass

- Mirrors